Add to Cart

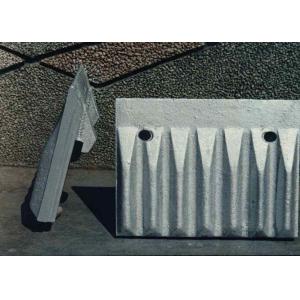

Jaw plate , Its material is KmTBCr26/GB/T8263,for the Slag crusher:

Slag crusher jaw plate is fixed on the adjustable jaw body, its material and heat treatment process is the same as the roller tooth plate, roll gap between tooth plate is adjustable, make slag crushing granularity is adjustable, slag crusher after normal export broken slag particles less than 25 x 25 mm, once appear big debris size after tooth roller, adjusting the gap, it can reduce the slag crushing particle size.

DGS-XXX series single roller slag crusher is mainly used for the slag crushing of the slag conveying system of power plant. The crusher has reasonable design, compact structure, strong crushing force, high temperature resistance, good airtightness, stable and reliable performance, and the characteristics as auto-control slag discharge, and adjustable slag crushing granularity

The single roller slag crusher can not only be used at wet slag working condition, but also the high temperature dry slag working condition, working together with the dry slag conveyor.

Technical Parameter and Characteristics:

According to the output, the single roller slag roller can be divided into three types: DGS830, DGS1200 and DGS60A, the respective output is ≤30t/h, ≤40t/hand ≤60t/h

Qingdao Kechengyi Environmental Protection and Electric Power Technology Co., LTD. has established perfect quality control system and carried out the manufacturing and management of the equipment according to the requirements of ISO9001 quality management system; In order to have better participation in the international thermal power field, the company has obtained relevant qualifications to directly import and export the power plant equipment and spares. The company has excellent research and development team and experienced production team, which makes the annual production capacity reaches 4000 tons. The products have been adopted by more than hundreds of power plants at home and abroad for the excellent product quality and after-sales service.